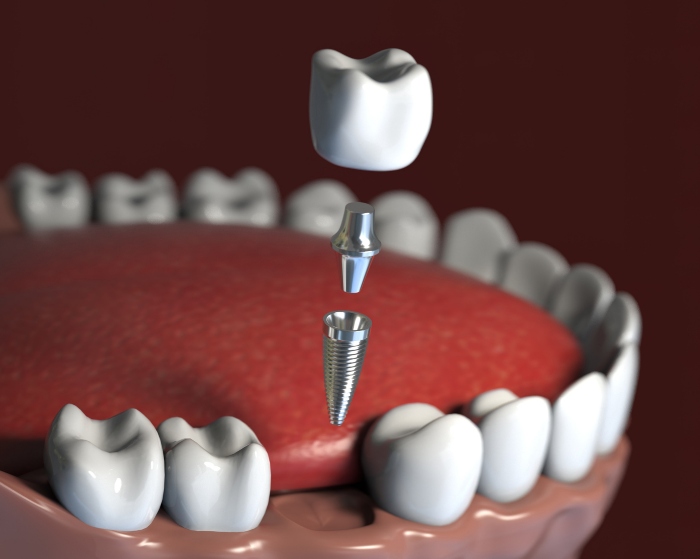

We support educational institutions by providing titanium components for research and engineering projects. Our titanium parts manufacturing services ensure students and researchers have access to high-quality materials for innovation and discovery.

01

01

Titanium is significantly more expensive than other commonly used materials like aluminum or stainless steel.

02

02

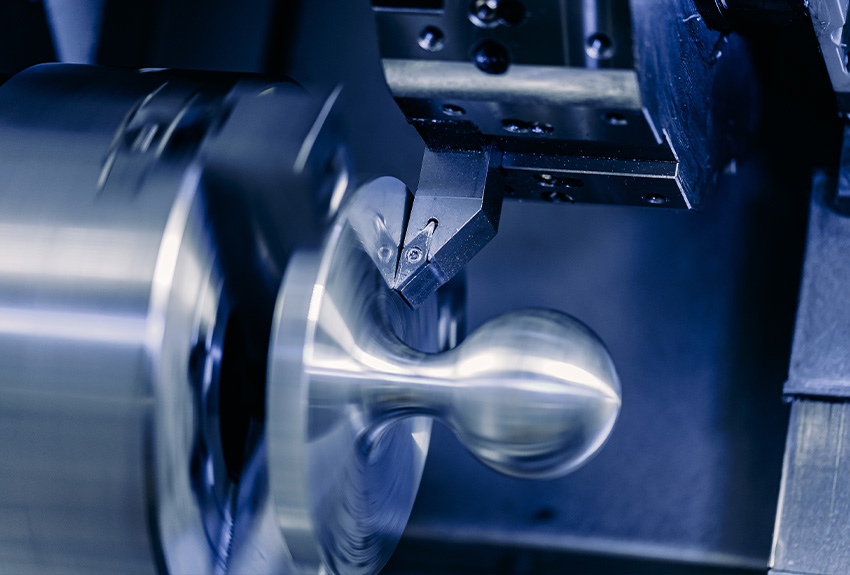

Titanium's low thermal conductivity and high chemical reactivity make it challenging to machine, often leading to tool wear and poor surface finishes.

03

03

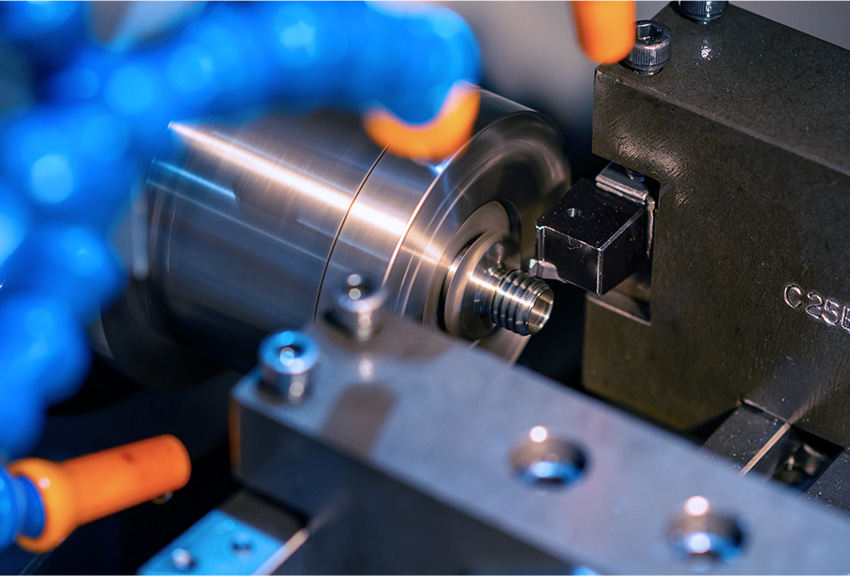

The processing of titanium materials is costly and has a relatively long production cycle. While ensuring high-performance requirements for components, manufacturers face the dual challenge of maximizing cost-effectiveness and significantly improving production efficiency.

Delivering high-quality titanium products that meet or exceed industry standards and customer expectations.

Continuously investing in research and development to advance titanium manufacturing technologies and applications.

Focusing on understanding and fulfilling customer needs, providing tailored solutions and exceptional service.

Great quality and functional design. The product was spot on and easy to work with supplier. Thank you.

Excellent quality, service, and price shipped to the US. Highly recommend.

A pleasure to do business with every time. Good quality service and delivery.

Related News

Choosing us is choosing excellent quality!