We supply titanium parts of high-performance for sports equipment, including bicycles, golf clubs, and tennis rackets. We supply titanium parts that enhance strength, reduce weight, and optimize performance for athletes at all levels.

01

01

Titanium is significantly more expensive than traditional materials like aluminum, steel, or carbon fiber, which can increase the overall cost of sporting equipment.

02

02

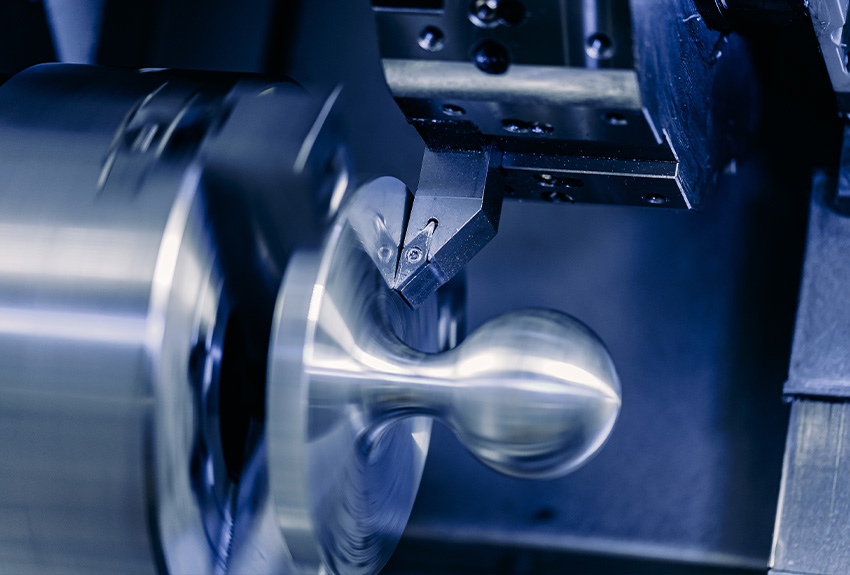

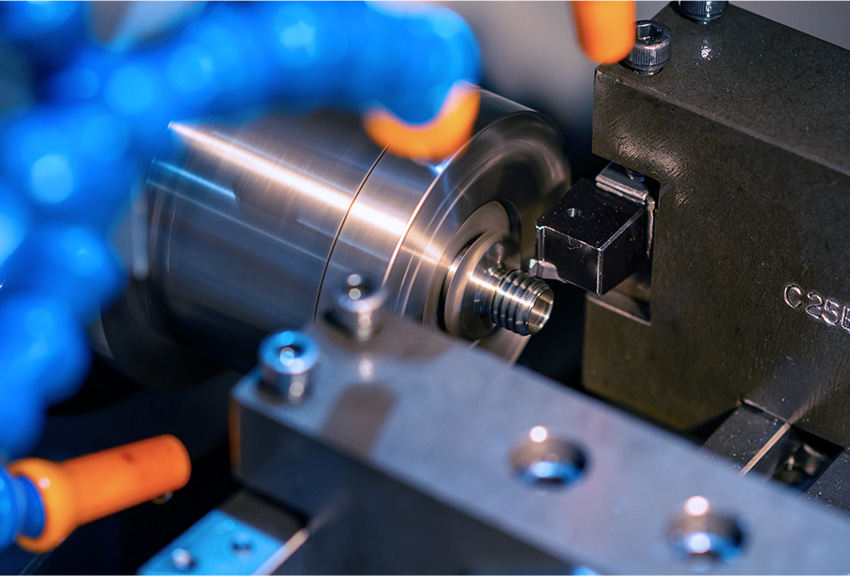

Titanium's low thermal conductivity and high chemical reactivity make it difficult to machine and process, requiring specialized equipment and techniques.

Processes such as CNC machining, welding, and surface finishing demand precision and controlled environments, increasing production complexity and costs.

03

03

The processing of titanium materials is costly and has a relatively long production cycle. While ensuring high-performance requirements for components, manufacturers face the dual challenge of maximizing cost-effectiveness and significantly improving production efficiency.

We are committed to breaking through the limitations of traditional machining technologies by adopting the most advanced five-axis simultaneous NC machining, laser interferometry, and Computer-Aided Design/Manufacturing (CAD/CAM) technologies to achieve ultra-precision machining of titanium parts.

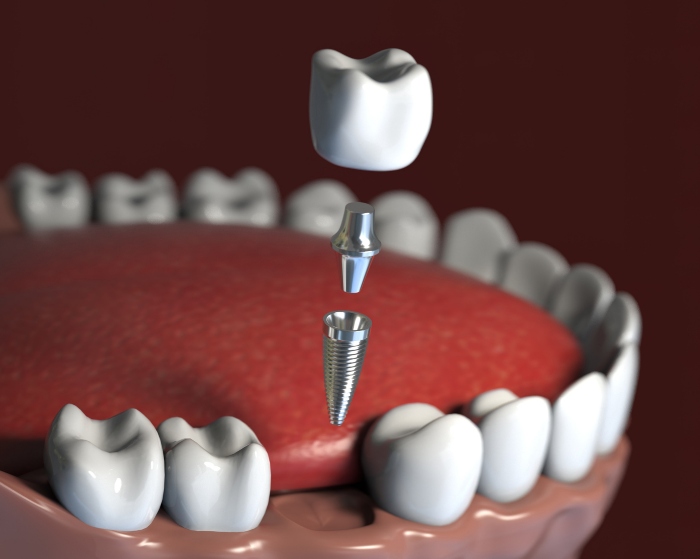

In the aerospace industry, we strive for precise control of titanium material properties. Through sophisticated heat treatment processes and a rigorous quality management system, we ensure that each titanium part possesses exceptional mechanical properties and durability.

In the ongoing battle between cost-effectiveness and production efficiency, we adopt an innovative approach. By continuously optimizing production processes, introducing intelligent manufacturing technologies, and implementing refined management, we achieve dual optimization of cost and efficiency while maintaining the exceptional performance of titanium parts.

Great quality and functional design. The product was spot on and easy to work with supplier. Thank you.

Excellent quality, service, and price shipped to the US. Highly recommend.

A pleasure to do business with every time. Good quality service and delivery.

Related News

Choosing us is choosing excellent quality!