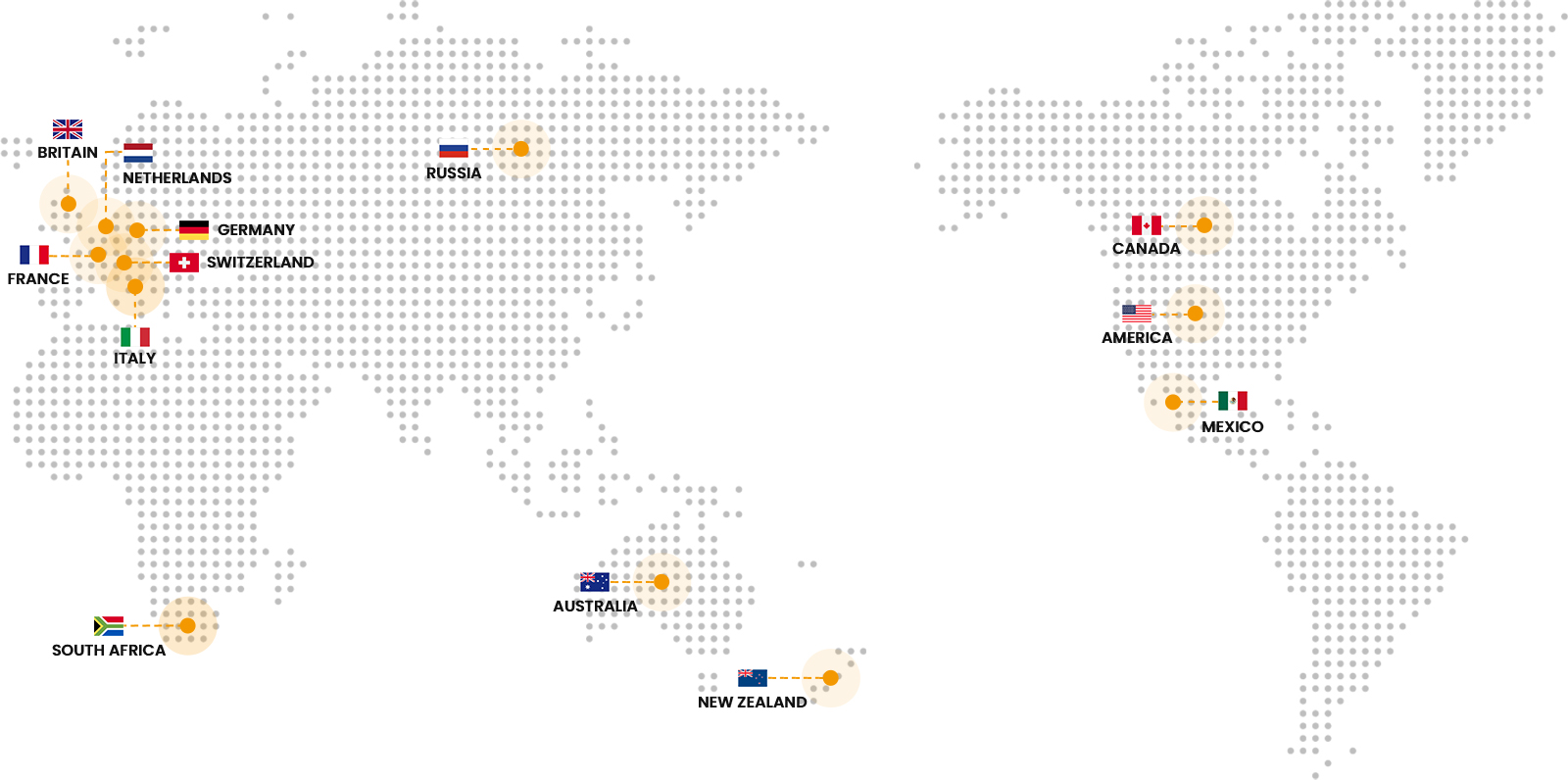

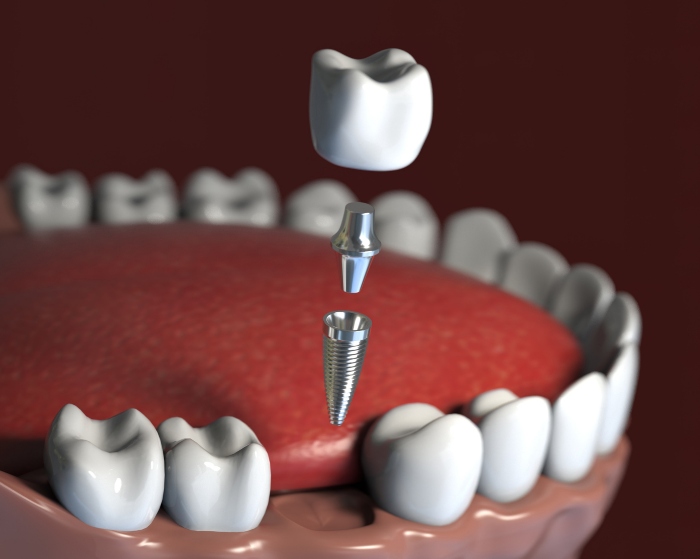

Titanium parts manufacturing plays a crucial role in the aerospace industry. With lightweight, high-strength titanium components, we deliver precision-engineered parts to meet the stringent requirements of aircraft and spacecraft. Trust us to supply titanium parts for optimal performance in extreme environments.

01

01

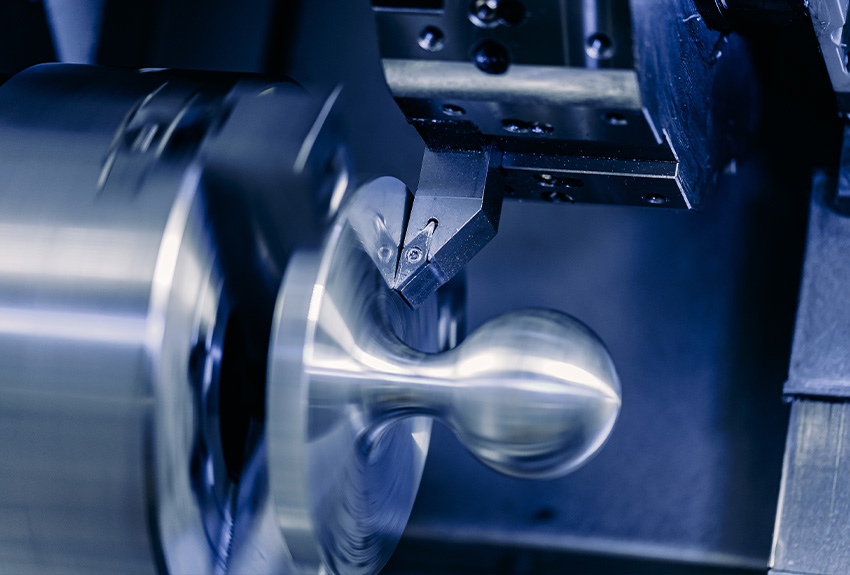

The unique physical properties of titanium materials—including high strength, low thermal conductivity, and susceptibility to oxidation—demand the application of high-precision machining techniques during processing. These advanced methods ensure the dimensional accuracy and surface quality of components, enabling us to meet the stringent requirements of industries such as aerospace, medical, and automotive. By using the latest technology, we overcome the challenges posed by titanium's characteristics, delivering superior performance and reliability in every component.

02

02

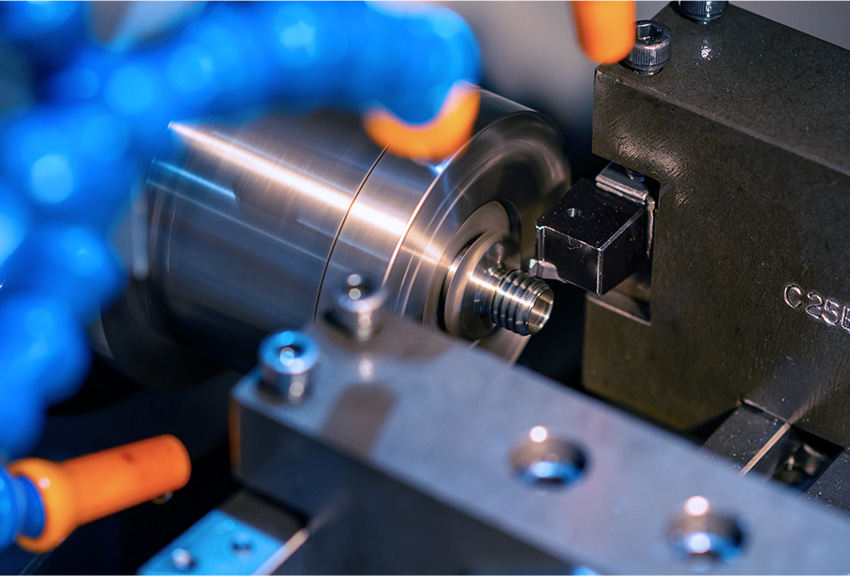

The performance stability of titanium materials is crucial for aerospace components, especially under extreme temperatures and stress environments. Each batch of titanium materials must demonstrate impeccable consistency and reliability. This is not only a requirement for the material itself but also an ultimate test of heat treatment processes, material testing technologies, and quality control.

03

03

The processing of titanium materials is costly and has a relatively long production cycle. While ensuring high-performance requirements for components, manufacturers face the dual challenge of maximizing cost-effectiveness and significantly improving production efficiency.

Delivering high-quality titanium products that meet or exceed industry standards and customer expectations.

Continuously investing in research and development to advance titanium manufacturing technologies and applications.

Focusing on understanding and fulfilling customer needs, providing tailored solutions and exceptional service.

Great quality and functional design. The product was spot on and easy to work with supplier. Thank you.

Excellent quality, service, and price shipped to the US. Highly recommend.

A pleasure to do business with every time. Good quality service and delivery.

Related News

Choosing us is choosing excellent quality!