We have strict standards for technology and quality

Just to better serve you

The meticulous examination of drawings, rigorous selection of high-quality titanium materials, precise calibration of equipment, all ensure worry-free production commencement.

Drawing Review: Our engineering team rigorously reviews customer-provided drawings to ensure design rationality, precise dimensions, and to avoid any potential obstacles in the production of custom titanium parts.

Material Selection: We select high-purity CNC machining titanium materials that comply with international standards, ensuring product quality from the source.

Equipment Calibration: Before production begins, all equipment on the production line undergoes thorough inspection and calibration to ensure machines are in optimal working condition, laying the foundation for efficient production of custom made titanium parts.

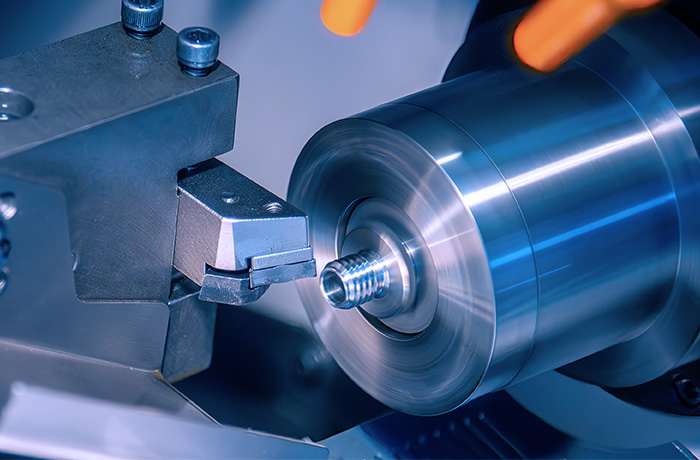

The adoption of advanced processing technology, continuous monitoring of process parameters, strict control over the production process, and meticulous attention to detail enable us to create customized CNC titanium parts of exceptional quality.

Advanced Processing Techniques: Utilizing advanced technologies such as titanium CNC machining, laser cutting, and cold/hot forming ensures processing accuracy and surface smoothness.

Process Monitoring: Real-time monitoring of key process parameters such as temperature, pressure, and speed during production allows for timely adjustments to ensure stable product quality of custom titanium machined components.

Process Management: Strict adherence to the ISO quality management system and refined management of the production process ensure that every step of the operation complies with specifications for CNC titanium machining excellence.

Implement comprehensive quality inspection, fine packaging protection, rapid response to after-sales, and ensure customer satisfaction without worries

Comprehensive Quality Inspection: After the completion of products, whether manufactured through CNC titanium machining or other metal processing methods, each item undergoes rigorous full-dimensional inspection, performance testing, and appearance checks to ensure it meets the highest quality standards.

Precise Packaging: Using professional shockproof and rust-proof packaging materials provides comprehensive protection for custom titanium parts, ensuring they remain unharmed during transportation. This guarantees the safe delivery of your CNC machined titanium parts with uncompromised quality.

Prompt After-Sales Service: We have established a comprehensive after-sales service system to quickly respond to customer needs, providing technical support, repairs, and return or exchange services, giving customers peace of mind. If you have any questions about titanium CNC service or your custom CNC titanium parts, our team is ready to assist you—just reach out!

105

+Customization Cases

200

Million UnitsCustom Titanium Parts

16

YearsTitanium CNC Machining Service

99

%Customer Satisfaction Rate

Providing industry leading quality products and service globally.

0917-6753303

+86-186-2391-9905

+86 18623919905

C4 Workshop, North Area of High Tech Auto Parts Business Incubation Base, FengHuang 10th Road, High Tech Development Zone, Baoji City, Shaanxi Province, P.R. China 721013