Forecast The Development Of Titanium Material Market From The Future Fleet Size And New Aircraft Delivery Volume in China And The World

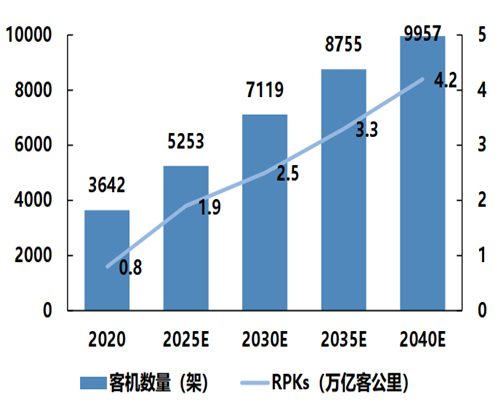

According to the COMAC Market forecast annual report (2021-2040), in the next two decades, the global air passenger turnover (RPKs) will increase at an average rate of 3.9% per year, and China's air passenger turnover will grow at an average rate of 5.7% per year; it is expected that about 41,429 new aircraft will be delivered, worth about USD$66.1 trillion (based on the 2020 catalog price); Chinese airlines will receive 9,084 of them, with a market value of about USD$11.4 trillion (based on the 2020 catalog price); Chinese airlines will receive 9,084 of them, with a market value of about USD$11.4 trillion (based on Based on catalogue prices in 2020); by 2040, China's share of the global airliner fleet will grow from 20% to 22%, making it the world's largest single aviation market.

From a structural point of view, among the new aircraft delivered to the Chinese market in the next two decades, 6,295 single-channel jetliners, accounting for nearly 70% of the total delivered in the next two decades, of which 78% of the single-channel jetliners fleet is 160-seat; 1,836 dual-channel jetliners, accounting for 20% of the total delivered, accounting for 71% of the total delivered dual-channel jetliners; the rest are jet regional airliners, 953 will be delivered in 20 years, all of which are 90-seat. C919 is a 158-168-seat single-channel airliner. Assuming that it will occupy 25%-30% of the domestic single-channel airliner market share in the future, it is expected to deliver an average of about 80-90 aircraft per year, with corresponding sales of about 8-9 billion US dollars. According to COMAC's official website, C919 currently has a total of 815 orders from 28 customers.

The amount of titanium alloy used in Airbus aircraft is relatively stable, lower than that of steel, but with the gradual increase of the amount of composite materials, the amount of steel decreases, while the amount of titanium alloy gradually increases. For example, the amount of composite materials for Airbus has increased from 5.5% of the third-generation airliner A320 to 8% of the fourth-generation airliner A340, and the corresponding amount of titanium has increased from 4.5% to 6%. The amount of composite materials for A380 airliners has reached 25%, and the amount of titanium alloy has increased to 10%. Except for Boeing 787, the A350 is currently the model with the most used composite materials, with an amount of about 52%, and the corresponding amount of titanium alloy has also increased to 14%. The main parts of the titanium alloy used in the A350 airliner include the engine suspension, hatch, wing structure, seat rail, landing gear, and the heat insulation screen of the auxiliary power cabin.

The amount of titanium alloy for C-series aircraft has reached 8%. The rear beam frame and tail cone butt frame of the middle fuselage are made of Ti-6Al-4V with good compatibility with conforming materials, and the APU firewall is made of pure titanium sheet. Considering the strength, stiffness and impact resistance, titanium alloy materials are generally used for hatch blocks and some important joints.

The amount of titanium alloy in the airframe structure of some aircraft in our country is also constantly increasing. The amount of titanium alloy used in the commercial airliner ARJ21 is 4.8%, while the amount of titanium used in the C919 airliner has reached 9.3%, which is slightly higher than that of the Boeing 777. Compared with the Boeing 777, the Boeing 777 is 8%. The titanium alloys used in C919 aircraft are CP-3, Ti-6Al-4V and Ti-55531. The main parts are the head, hanging, tail, outer wing and central wing box. It is predicted that in the next three years, China's civil aviation titanium will reach a new height of 20,000 to 25,000 tons/year.