OPPO's Sky Dome Architecture Technology Release Conference

Author:BOZE

Time:2025-02-14

View:19271

On February 13th, 2025, OPPO held a press conference on the Sky Architecture technology in the Jurong Bay Park, officially unveiling the core technological breakthroughs of the current world's thinnest folding flagship OPPO Find N5. As an important technology partner of OPPO, Xue Lei, the Chairman and General Manager of Platinum 3D, was invited to attend the event and shared the innovative practices of both parties in empowering the 3C industry with metal 3D printing technology.

The OPPO Find N5 boasts a record-breaking thinness of 8.93mm in its body thickness, breaking the industry record and becoming the thinnest foldable flagship device globally. This model adopts OPPO's latest generation Sky Canvas architecture and titanium alloy Sky Canvas hinge, achieving triple waterproof certifications of IPX6, IPX8, and IPX9. It also becomes the first foldable flagship device to obtain dual certifications of no-slippery-fold and fold-free worries from Germany's TÜV Rheinland, significantly enhancing the reliability and service life of the foldable screen, and redefining the industry standard.

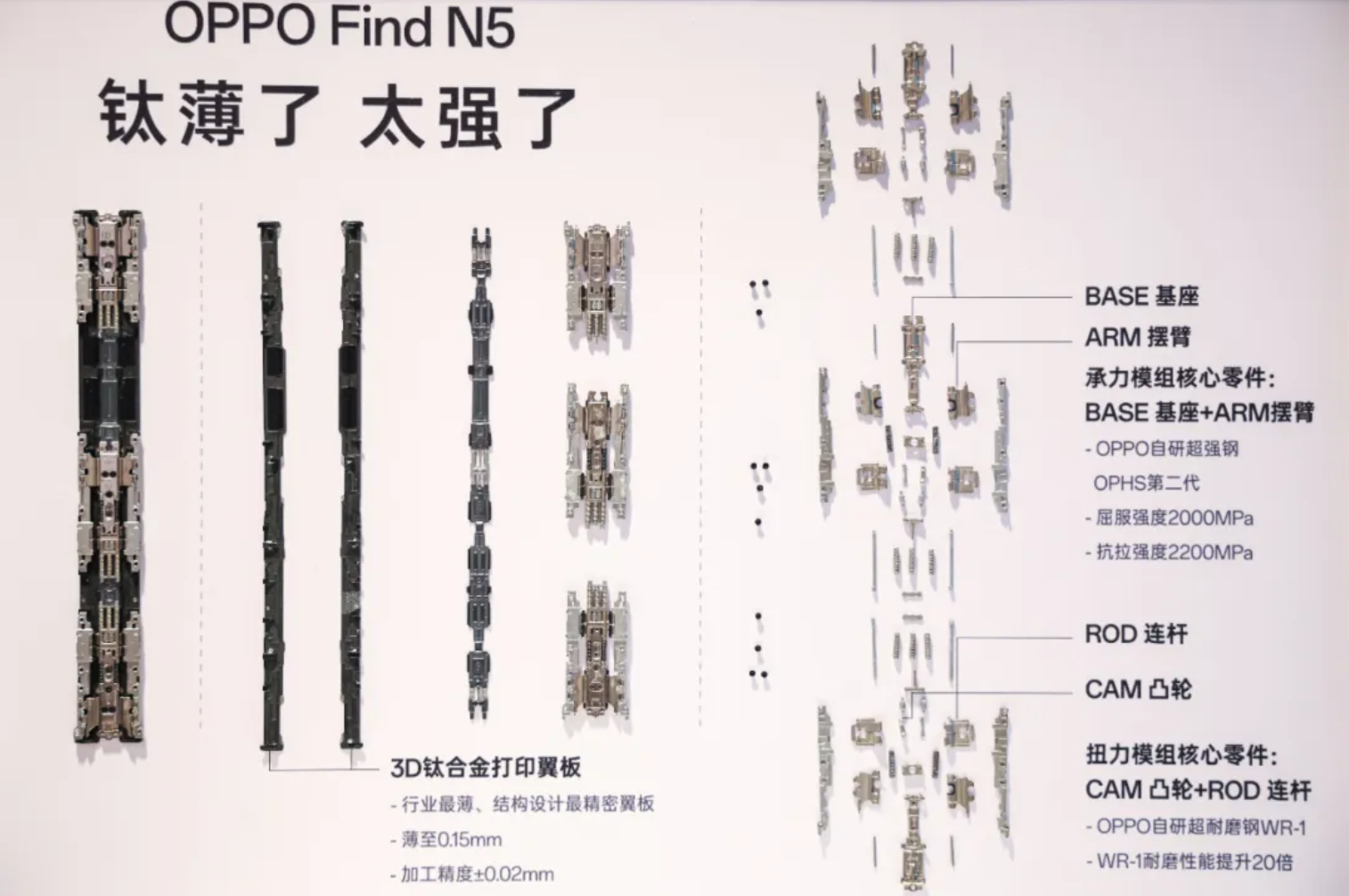

As one of the core elements of the design of OPPO Find N5, the hinge system directly determines the durability, crease control and overall feel of the foldable phone. During the development of OPPO Find N5, Platinum 3D Metal Printing Technology was adopted by OPPO to manufacture the main structural components of the Sky Dome hinge - the wing plate and the outer rotating shaft frame. This helped OPPO create a lighter, thinner and stronger folding structure.

The hinge wing plate is the key component of the entire hinge. When the screen is folded and closed, it shapes the water-drop-like form of the screen axis. When unfolded, it supports the flatness of the flexible screen and provides a buffering and energy-absorbing function in case of accidental drops or bumps. The breakthrough in its manufacturing process directly affects the reliability and service life of the foldable screen.

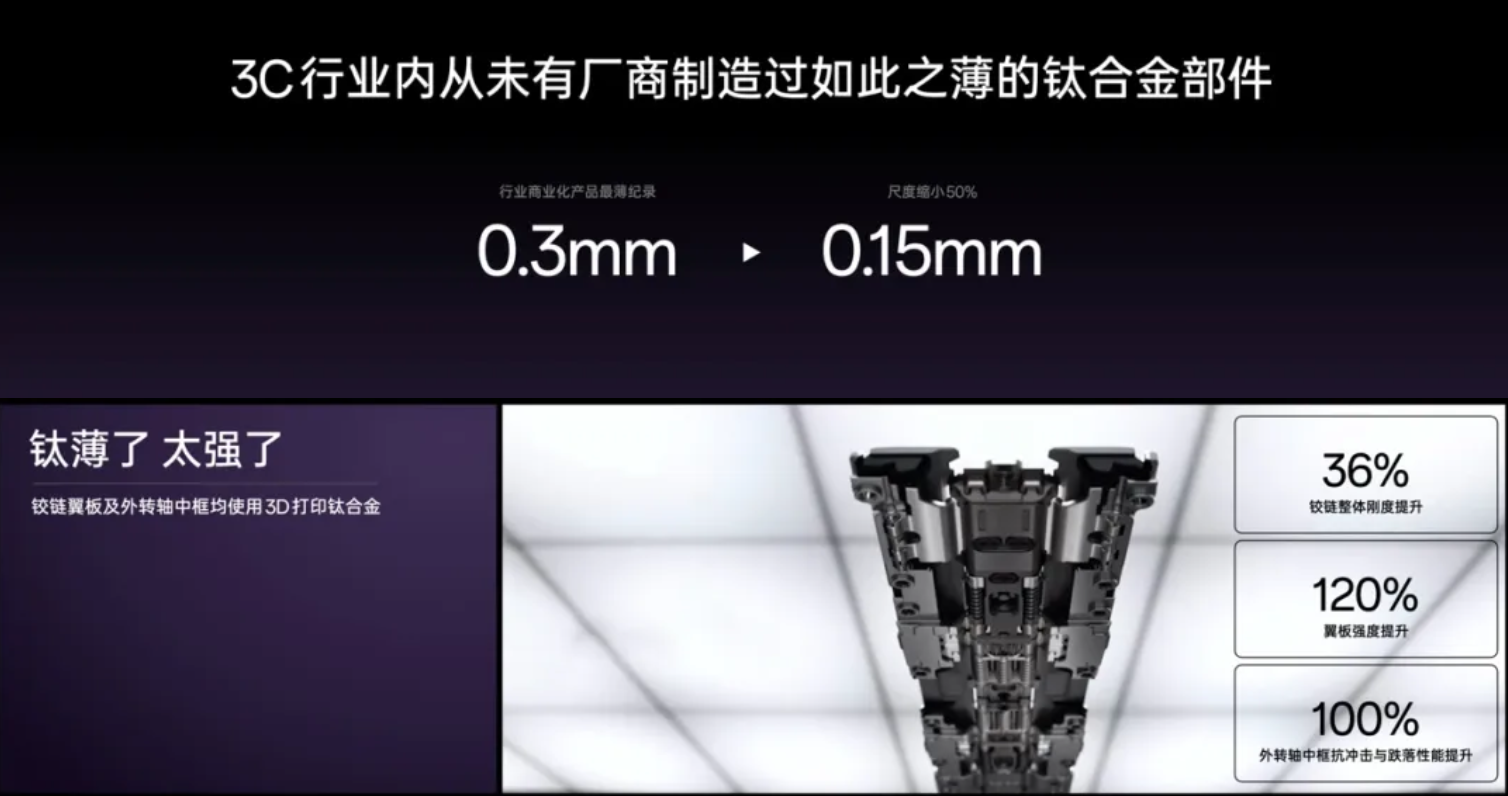

After a joint R&D effort lasting over a year between Piletek and OPPO, the company fully leveraged the advantages of metal 3D printing technology and broke through the traditional processing limits. Through 28 precise processes, they were able to produce 300 of the thinnest titanium alloy structural components globally per batch within 25 hours. This achievement reduced the minimum scale record of commercialized 3D-printed titanium alloy products from 0.3mm to 0.15mm. Meanwhile, the overall rigidity of the hinge was enhanced by 36%, the strength by 120%, and the anti-shock capability of the core components by 100%, ensuring that the foldable screen mobile phone maintains higher durability while achieving a slim and lightweight design.

Furthermore, the ultra-high precision of metal 3D printing also contributed to OPPO Find N5 becoming the first foldable screen product to obtain the dual certifications of no creasing sensation and fold-free worries from TÜV Rheinland, providing users with a superior folding experience.