Expert Solutions in Custom High Precision Titanium Alloy Part

Time:2025-05-11

View:266

Our focus on custom high precision titanium alloy parts allows us to serve a multitude of industries requiring robust and lightweight materials. With a commitment to excellence, we ensure that every aspect of our operation reflects our dedication to quality and customer satisfaction.

Rigorous Pre-Production Procedures

Before we initiate the manufacturing process, our engineering team conducts a thorough drawing review to ensure design rationality and precise dimensions. This step is crucial as it helps avoid potential obstacles in producing custom titanium parts. We also place great importance on material selection, opting for high-purity CNC machining titanium materials that comply with international standards. This strategic choice assures product quality right from the source. Additionally, we perform rigorous equipment calibration to guarantee that all machinery is in optimal working condition, setting a solid foundation for the efficient production of custom-made titanium parts.

Precision During Production

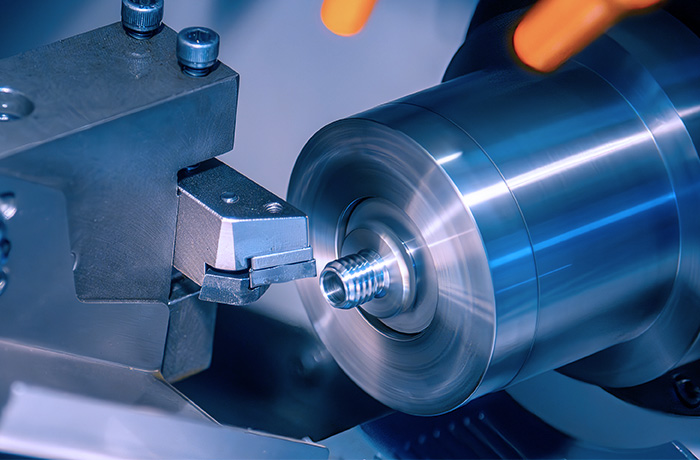

Our commitment to quality continues during the production phase. We utilize advanced processing techniques such as titanium CNC machining, laser cutting, and cold/hot forming to ensure processing accuracy and exceptional surface smoothness. Real-time monitoring is another key element of our approach; we closely track key process parameters, including temperature, pressure, and speed, allowing for timely adjustments that secure stable product quality. Furthermore, our strict adherence to the ISO quality management system ensures that every step of the production process meets specifications for CNC titanium machining excellence.

Comprehensive Post-Production Practices

After the completion of custom titanium parts, BOZE CNC-Ti implements comprehensive quality inspection measures. Each item undergoes full-dimensional inspection, performance testing, and appearance checks to ensure it meets the highest quality standards. Once inspected, we use professional shockproof and rust-proof packaging materials to provide comprehensive protection for custom high precision titanium alloy parts during transportation. This meticulous approach guarantees the safe delivery of your CNC machined titanium parts without compromising their integrity. To further enhance customer satisfaction, we have established a comprehensive after-sales service system, ensuring that we promptly address any customer needs with technical support, repairs, and return or exchange services.

Conclusion

In summary, BOZE CNC-Ti is your trusted partner for all custom titanium manufacturing needs. With rigorous pre-production procedures, precision during production, and comprehensive post-production practices, we are committed to delivering high-quality custom high precision titanium alloy parts tailored to your specifications. Our dedication to quality and customer service positions us as a leader in the industry. If you have any questions about our custom titanium parts or services, our team is always ready to assist you. Reach out to us today, and let's elevate your projects together!